Empowering hat-makers in Haiti through ethical fashion (en)

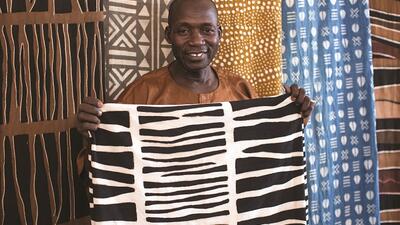

ITC’s Ethical Fashion Initiative (EFI) has since 2009 served as a bridge between some of the world’s poorest communities and some of its most prominent fashion brands, building skills and creating decent jobs for people from Burkina Faso to Haiti while delivering authenticity and artisanship to a growing network of companies such as Vivienne Westwood and Mimco.

International clients have in recent years approached the EFI requesting artisanal hat-making skills.

In Haiti, there is a long tradition of hat-making as a supplement to agricultural income by women who weave at home and pass their skills down from one generation to the next. Often women who are widowed will specialize in hat- making to provide for their families.

The EFI set out in 2016 to nd hat-makers to work with, making enquiries in Port-au-Prince and tourist areas outside of the city that ultimately led to a community of women hat-makers around the small village of Labiche near Côtes- de-Fer in the country’s south.

But while the hats they made were more than adequate for tourists, they fell short of the exacting standards of international hat-makers: the hats varied substantially in quality, in part a function of the fact that the women worked on their own rather than in a group.

The responseAfter assessing interest among roughly 100 hat-makers, ITC organized the 20 most motivated artisans into a cooperative, enabling more standardized production. The next step was to focus on improving the quality of hat- making through technical training.

First, Molly Yestadt, a New York-based hat-maker, travelled to the EFI’s Port-au-Prince hub to train the collective on straw quality, workability and cleanliness. She also gave a demonstration on blocking and forming techniques for shaping hats.

Next, the EFI developed a partnership with an Ecuadorian hat-making school, Escuela Taller Pile, from a region renowned for the country’s woven straw hats, better known as Panama hats, which have been classi ed by the United Nations Educational, Scienti c and Cultural Organization (UNESCO) as part of humanity’s intangible cultural heritage. As part of this South-South cooperation, skilled artisans from the school came to Haiti and shared technical knowledge on bre treatment, hat-weaving and hat- nishing.

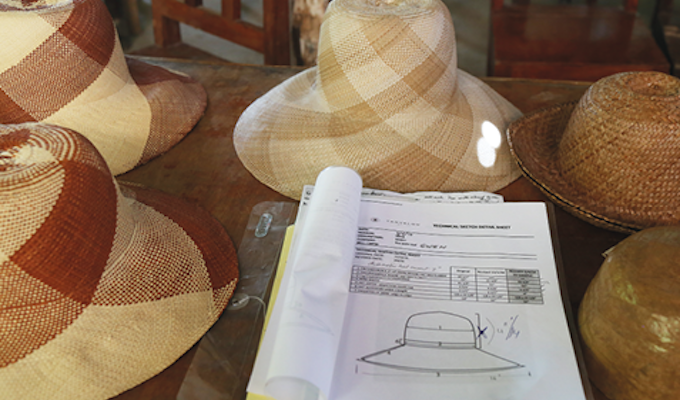

A new quality control system was put in place under which the 20 women worked in groups of three or four. A leader from each group reports to a weaver in charge of quality control, who in turn reports to the EFI hub in Port-au-Prince, which is responsible for customer relations, production management and nal quality control checks for all items produced in the country.

In addition, the EFI team provided technical expertise and quality control feedback, investing in hat-making tools and developing the Haitian artisans’ ability to decipher technical design sheets.

The resultsSince the hat-makers in Labiche started working with ITC, they have produced hats for three fashion brands – Tucker, Yestadt Millinery and Yanvalou Designs, three brands based in the United States. In the process, they have increased their incomes six-fold, from about 50 Haitian gourdes (or less than $1) to 300 Haitian gourdes (about $4.40) per day.

The futureThe principal aim is to strengthen existing partnerships and connect new United States and European buyers to the hat-making communities to generate greater sales, incomes and jobs. The expansion strategy also seeks to build links to the region’s tourism industry; the cruise company Royal Caribbean, for example, has expressed interest in purchasing mid-range hats for their customers.

Meeting increased demand will require improvements to the production capacities of the Haitian hat-makers. The EFI team will organize additional technical training and put in place processes to ensure that improved quality control practices continue to be implemented.