ITC Impact: Nigeria (en)

A shea butter cooperative in the town of Saki in Nigeria’s Oyo state has sold some 200 metric tons of its product to major cosmetics companies in Nigeria and the United States, and secured orders for a further 500 metric tons, following the implementation of a quality improvement programme by the Nigerian Export Promotion Council (NEPC) under ITC supervision.

The sales by the Ifedawapo Sheabutter Cooperative were enabled by its working relationship with Shea Origin Nigeria Limited, a company whose investment in the cooperative was facilitated by the project.

Considerable progress has been made towards enabling rural communities to increase their economic contributions and improve their standard of living, said Mobola Sagoe, CEO of Shea Origin Nigeria Limited. ‘Through the various skills, knowledge transfer and capacity building initiatives in Saki, a small town in the southwestern part of Nigeria is set to appear on the global shea map,’ she said.

Extracted from the nuts of the African shea tree, shea butter has been used for cosmetic purposes for thousands of years, and is today widely used in the global cosmetics industry to make skin moisturizers and hair-care products. It is also used in confectionery, mainly as a substitute for cocoa butter in chocolates.

To meet the demands of international buyers, however, shea butter needs to meet demanding purity and consumer safety standards.

Under the project, the lead funder, the Standards and Trade Development Facility, provided funds to purchase modern equipment for extracting butter from shea nuts, together with support for analysis and capacity building on improving product quality and safety. The community in Saki provided land, the local government provided some infrastructure, and the Nigerian Export Promotion Council (NEPC), the implementing agency for the project, provided the building to shelter the processing equipment.

The NEPC realized that the local cooperative that owned the facility lacked the capital, technical experience and know-how to manage it sustainably. To fill this gap, it brought in domestic investors from the shea butter sector with proven track records of working with rural producers.

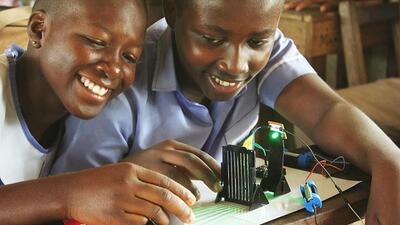

Producers were educated in safety management processes for minimizing fungus and aflatoxin levels, and educated about the importance of complying with sanitary and phytosanitary measures (SPS).

Thanks to the programme, the 120 small-scale shea nut buyers and processors belonging to the Ifedawapo Sheabutter Cooperative have had their shea butter samples certified by Nigeria’s regulatory body, the National Agency for Food and Drug Administration and Control (NAFDAC), as well as by internationally accredited laboratories in Ghana operated by SGS, the Swiss-based certification services company.

Another 130 shea nut processors, mostly women, are looking to join the Ifedawapo Sheabutter Cooperative so as to meet the sanitary and phytosanitary (SPS) measures required for exporting to the United States, said Afolabi Bello, Principal Trade Promotion Officer at the NEPC and Secretary for the project. Three other shea butter production facilities set up on similar lines elsewhere in the country are expected to become operational in 2015; similar cooperation is underway in the sesame sector.

‘The project has been of significant value to us’, said Olusegun Awolowo, executive director and CEO of the NEPC. ‘Until now, Nigeria has been unable to convert its comparative advantage as the world’s largest shea producer into a competitive edge in global marketing, largely due to quality constraints. However, thanks to the successful implementation of the project resulting in improved adherence and compliance to SPS measures, we are poised to become the global leader in shea exports.’

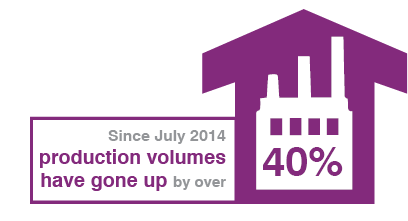

According to Bello, since processing started at the new facility in Saki in July 2014, production volumes have gone up by over 40%, and are commanding prices 20 to 25% higher than before.

In addition to the laboratory tests, Funmilayo Alabi, CEO of Atlanta-based Shea Radiance LLC, which produces and markets shea-based cosmetics, confirmed that the shea butter produced by the cooperative in Saki met the required standards. ‘The sample you sent me also meets the color and texture requirements that we find desirable in cosmetics,’ she wrote to an investor in the facility.

ITC backed up the NEPC with expertise in safety and quality improvement as well as project management as part of its mission to build the capacity of trade support institutions working with small and medium-size enterprises (SMEs) in developing countries.

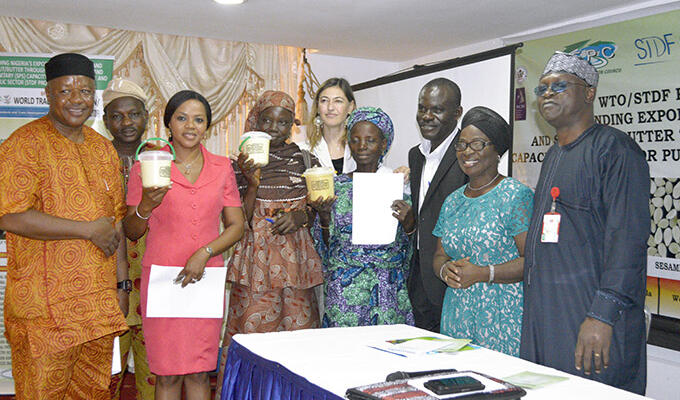

‘The NEPC did a marvelous job in pulling all the public and private stakeholders together and delivering results,’ said Ludovica Ghizzoni, who oversaw the project at ITC.

The Standards and Trade Development Facility is a global partnership that supports developing countries in building their capacity to implement SPS standards, guidelines and recommendations as a means to improve their human, animal, and plant health status and ability to gain or maintain access to markets.

The project mobilized support from other sources, including the law firm Sidley Austin, which helped develop, on a pro bono basis, a Memorandum of Understanding between prospective investors and the cooperatives (together with the NEPC) for fair and sustainable management processes.

According to an independent evaluation by the Tony Elumelu Foundation, a non-profit organization dedicated to promoting private sector growth in Africa, the project was ‘effective in developing the skills and reducing the knowledge gap among farmers, extension officers and standards enforcers, particularly as related to aflatoxin critical control points.’